Exploring the different microcement products on the market today and what best suits your needs.

What is Microcement?

Microcement, also known as microtopping, microcemento, microscreed or microcrete, is a versatile decorative coating material mainly used in interior and sometimes exterior design.

Traditional microcement is a cementitious product that consists of a mixture of cement, fine aggregates, polymers, and additives. It is called “micro” cement because it has a thin layer application compared to traditional cement.

Microcement is well renowned for its versatility and can be applied to various surfaces, including floors, walls, countertops, and furniture. It can be used to achieve a seamless, smooth, and contemporary finish that resembles polished concrete or cement-like textures.

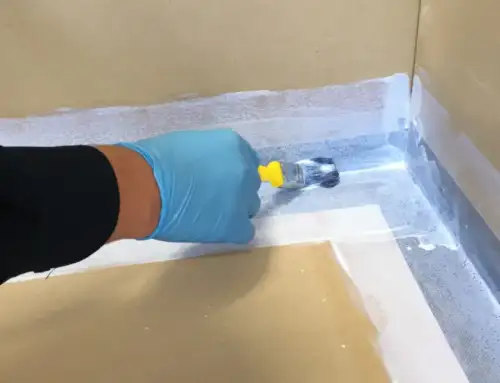

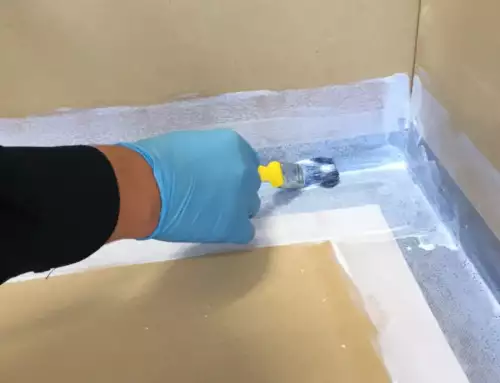

The Microcement application process involves preparing the surface, applying a bonding agent (primer), and layering the microcement mixture in multiple layers. It is typically applied in thin layers, ranging from 2-3mm as a total thickness, allowing it to adhere to existing surfaces without requiring extensive modifications.

One of the key advantages of microcement is its excellent adhesion properties, which allow it to be applied over various substrates such as concrete, tiles, wood, and even existing coatings. Microcement generally offers a durable and hard-wearing decorative surface that poses good resistance to cracking, abrasion, and impact if installed correctly with high-quality products.

Microcement is available in various colours and finishes, suitable for domestic, retail and commercial environments. It can be customised with pigments and decorative techniques to create unique and stylish designs.

Due to its versatility, durability, and aesthetic appeal, microcement has gained popularity in contemporary architecture and interior design, providing a modern and industrial look to various spaces.

In this article, we will explore the different types of microcements products available on the market, including epoxy, mono-component (powder & water), bi-component (powder & polymer) and acrylic microcement systems.

We have provided a brief overview of each type. We discuss their benefits and advantages. We also touch upon sustainability and ease of use.

Mono-Component Microcement (powder + added water)

Mono-Components, often referred to as traditional microcement, involve mixing a powdered component with water to create a workable paste which is then applied to surfaces, allowed to dry / cure before further layers are applied, sanded and sealed. Mono-Component microcements are well known for their ease of use and versatility in application in creating a concrete effect finish indicative of traditional polished concrete.

Benefits:

- Environmentally friendly with minimal VOC emissions.

- Straightforward and easy-to-follow mixing process (add the correct quantity of clean water and pigment).

- Compatible with water-based liquid pigments to create almost any colour.

- Good workability and smooth finish.

- Suitable for various stable surfaces with the correct preparation.

- Suitable for floors, walls and any other stable surface.

Advantages:

- Quick drying time compared to other microcement types.

- Customisable with a wide range of colours, textures and finishes.

- Suitable for both professionals and DIY enthusiasts.

Disadvantages:

- May require additional sealants or coatings for enhanced durability and water resistance.

- It can be more prone to cracking in rare cases when not applied properly or maintained in accordance with recommendations.

Sustainability:

Mono-Component are the most eco-friendly microcements, which are generally considered more sustainable than any other systems on the market, with minimal VOC emissions in the application process, less energy-intensive production process, and recyclability due to the inclusion of natural and cementitious materials, making this a popular choice if committed to sustainable practices and a low carbon footprint.

Ease of Use:

Mono-Component microcements are relatively easy to use, making them suitable for both professional and DIY projects. However, as with all microcement systems, the correct surface preparation and attention to mixing ratios are crucial for achieving the desired results.

Bi-Component Microcement (powder + added polymer liquids)

Bi-Components microcement requires the addition of liquid polymer additives into the powder mixture. Polymers enhance its adhesion, flexibility, durability and working time during installations.

Benefits:

- Improved adhesion and flexibility.

- Enhanced durability and impact resistance.

- Suitable for various surfaces and environments.

- Easily customisable with different colours and finishes.

- Higher resistance to water (some systems are 100% waterproof without sealers)

Advantages:

- A higher degree of resistance to minor movements and vibrations.

- Offers good adhesion to the substrate.

- Provides good durability and impact resistance

- Longer working times during application due to polymer additions

Disadvantages:

- Requires the correct surface preparation and mixing techniques.

- May have longer drying / curing times compared to other microcement types.

Sustainability:

The sustainability of Bi-Component Microcement depends on the specific polymer additives used. Look for products that incorporate environmentally friendly and low-VOC polymer resins to minimise environmental impact. Overall due to the reduced energy-intensive production process, recyclability and inclusion of natural and cementitious materials, this is also a popular choice if committed to sustainable practices.

Ease of Use:

Powder and polymer microcement requires proper surface preparation and mixing techniques. It may be slightly more challenging to work with than the powder and water counterparts but it can still be manageable for experienced DIYers or professionals.

Epoxy Microcement

Epoxy microcement combines the benefits of the properties of epoxy resins. It is known for its exceptional durability, chemical resistance, and ability to create a seamless finish. Epoxy systems are a popular choice for high-traffic areas and commercial spaces due to their ability to withstand heavy footfall and their resistance to abrasion and chemicals. It offers a wide range of design options and is available in various colours and textures. However, epoxy microcement requires detailed application techniques and expertise for optimal results.

Benefits:

- Superior durability and chemical resistance.

- Provides a seamless and smooth finish.

- Excellent adhesion to the substrate.

- Suitable for floors, walls, bathrooms & wetrooms

Advantages:

- Suitable for high-traffic areas.

- Resistant to abrasion and chemicals.

- Customisable in terms of colour and texture.

Disadvantages:

- Requires professional application for best results.

- Longer curing time compared to other microcement types.

- Often does not look like a natural product and has a plastic appearance.

- Generally, a higher cost for materials and installation

Sustainability

Epoxy microcements are generally NOT considered a sustainable option due to its synthetic nature, lack of cementitious content and the energy-intensive production process in manufacturing epoxy resins. However, some manufacturers offer low-VOC (volatile organic compounds) options, which can reduce their environmental impact, yet are still not as environmentally friendly as traditional systems.

Ease of Use

Epoxy microcement systems generally require significant surface preparation, skilled application techniques, and an understanding of epoxy resin materials. Typically, this process is more challenging than other types, which require professional installation.

Acrylic Microcements

Acrylic microcement often comes pre-mixed and ready to use, eliminating the need for on-site mixing and, in some cases, pre-pigmented to the chosen colour. Acrylic versions offer enhanced adhesion, durability, flexibility and an extremely high degree of resistance to water and staining even before sealers are applied.

Benefits:

- Convenient and ready-to-use formulation.

- Easy application directly from the bucket of ready mixed materials.

- Good adhesion and high resistance.

- Extremely versatile with almost unlimited design options.

- Suitable for floors, walls, bathrooms & wetrooms

Advantages:

- Time-saving with no need for extensive on-site mixing.

- Fast curing due to no added water or polymers

- Quick installation process

- Almost no waste materials are generated

- Any unused materials can be sealed and reused at a later date

- Offers very good adhesion and durability.

- Customisable with a range of colours and finishes.

- A popular choice for professionals and DIY enthusiasts

Disadvantages:

- Generally, a higher cost for materials than traditional microcements (Mono-Component & Bi-Component, but cheaper than Epoxy)

Sustainability:

The sustainability of acrylic microcement depends on the specific acrylic resins used. Look for products that prioritise environmentally friendly resins and have low VOC emissions.

However, due to the lack of waste materials as a result of the materials being ready to apply, these pose many advantages of limited waste entering lanfills. In addition, some acrylic-based systems also include the addition of cementitious-based material, which increases their LEED / BREEAM sustainability values.

Ease of Use:

Acrylic microcement is designed for easy application and is suitable for both professionals and DIY enthusiasts. It eliminates the need for on-site mixing, simplifying the installation process.

Conclusion:

Microcement offers a versatile and decorative solution for various surfaces, and different types of microcements cater to different needs.

Whether you choose epoxy microcement for its durability, a Mono-Component microcement for its ease of use, Bi-Component microcement for its flexibility, or an Acrylic microcement for its convenience, there are options available to suit your specific project requirements.

Consider factors such as sustainability, ease of use, and the expertise required for proper installation when selecting the right microcement system for your project.